What are industrial Concrete flooring and the use of hardened concrete?

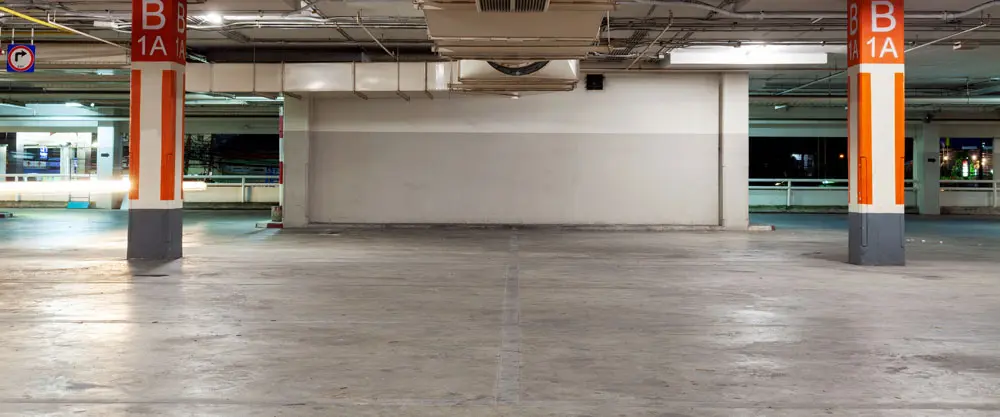

Industrial flooring and hardened concrete flooring in the automotive industries, printing and packaging industries, military centres, airports, metro and railway stations, and docks. Industrial flooring is generally applied to concrete and floor surfaces for a variety of purposes. Most of their properties protect the surface against abrasion, erosion and create beauty, cleanliness, integrity and the ability to scratch.

Coloured concrete flooring is the first word in the world because it makes the floor one-handed. Flooring, which is done under the name of industrial flooring, has many advantages, including the fact that coloured concrete flooring is anti-wear.

It is true to say that concrete literally provides the base for the vast majority of industrial enterprises all over the world. A well designed and constructed concrete floor offers a wide range of features such as high wear resistance, long life and ability to carry very heavy loads. Unfortunately, floors are not given the attention they deserve by investors, designers and contractors at the planning and construction stage. It is usually only when a floor fails to perform to the required standards that it becomes the focus of attention by which time it is too late to avoid necessary repairs or replacements. We have all seen industrial floors that become unusable due to cracking, breaking up and becoming uneven, giving a large amount of dust, all of these problems lead to lost production time and expensive repairs.

Fully cured, hardened concrete flooring must be strong enough to withstand the structural and service loads which will be applied to it and must be durable enough to withstand the environmental exposure for which it is designed. If concrete is made with high-quality materials and is properly proportioned, mixed, handled, placed and finished, it will be the strongest and durable building material. Concrete is a highly complex heterogeneous material whose response to stress depends not only on the response of the individual components but also upon the interaction between those components.

The properties which determine the quality of the hardened concrete broadly fall into the following three groups :

- Strength.

- Dimensional stability.

- Durability

Strength of Hardened Concrete Flooring

The compressive strength of concrete is the most common measure for judging not only the ability of the concrete to withstand load but also the quality of the hardened concrete flooring.

Test results obtained from compressive strength tests have proved to be sensitive to changing mix materials and mix proportions as well as to differences in curing and compaction of test specimens. The most significant factor influencing compressive strength is the amount of cement in the mix, relating to water: cement ratio (W/C).

Dimensional Stability (Creep and Shrinkage)

Dimensional stability of a construction material refers to its dimensional change over a long period of time. If the change is so small that it will not cause any structural problems, the material is dimensionally stable. For concrete, drying shrinkage and creep are two phenomena that compromise its dimensional stability.

Durability of Concrete

- Durability is the ability of concrete to withstand the conditions for which it is designed without deterioration for a long period of years.

- The durability of concrete may be defined as the ability of concrete to resist weathering action, chemical attack, and abrasion while maintaining its desired engineering properties.

- Durability is defined as the capability of concrete to resist weathering action, chemical attack and abrasion while maintaining its desired engineering properties.

Different concretes require different degrees of durability depending on the exposure environment and properties desired. For example, concrete exposed to tidal seawater will have different requirements than indoor concrete.

Industrial flooring is mostly implemented in industrial towns and the implementation of industrial flooring is done with a butterfly trowel. Concreting with a butterfly trowel has opened the ground for large projects that today, even in water treatment tanks, industrial flooring is used. The reasons for using a butterfly trowel in the implementation of industrial flooring is that both the quality of work and the amount of execution area increases.

Execution of concrete with a butterfly trowel in wet areas is time-consuming and it takes longer than hot and dry areas for the concrete to be finally polished. The price of butterfly concreting in cold areas is different from the price of butterfly concreting in warm areas. It becomes a butterfly with a trowel in these 2 areas.

In order to implement industrial flooring, we must first know the use of flooring in order to determine the method of execution. It is better to make the working floor resistant in the implementation of industrial flooring.